Buat para sesama praktisi Industri Kelautan, Perkapalan, Offshore Oil & Gas, Logistik, Supply Chain. Juga para peminat bidang kajian Operation management, Ship management, Project Management, Ship Design, Naval Archt & Marine Engineering, Health & Safety Dan yang terakhir juga buat sesama insan penempuh perjalanan di dunia. Bermaksud semata untuk berbagi dengan tanpa kehendak untuk menggurui.

Jumat, 28 Oktober 2011

Pressurized LNG concept, is it the right answer for the Indonesian problems of stranded / abandoned gas reserves?

Minggu, 31 Juli 2011

Tokoh-tokoh muda di balik Panggung Kebusukan yang tiada kunjung berakhir

By Agung Aang on Friday, July 29th, 2011, at 03.45 PM

Sebenernya aku malas untuk memulai tulisan ini, karena aku yakin tidak akan merubah apapun, tidak juga memberikan dampak apapun bagi kondisi masyarakat bangsa yang sedang terjangkit kangker ganas stadium lanjut ini…pheffww.

Ahhh ...biarlah setidaknya aku meneriakkan ini untuk diriku sendiri dengan maksud melepas seluruh energi negatif,..atau setidaknya kelak aku akan malu pada tulisan ini dan segera bertobat…jika suatu saat kelak aku dan kesadaran moral dan intelektual-ku mulai pula terjangkit kangker ganas kebusukan, kemunafikan kronis, akibat virus jahat korupsi yang sedang mewabah ini. Virus yang sudah sedemikian kronisnya menyerang sendi sendi dan syaraf peri kehidupan masyarakat bangsa ini.

Sudah selama berminggu-mingu terakhir ini kesadaran moral dan intelektual masyarakat kita di jejali dan dicekoki dengan penampilan panggung-panggung pementasan kebusukan profesional yang bak panggung teatrikal kelas atas yang celakanya terasa tanpa kunjung berakhir, bergeming tanpa malu terus menampilkan adegan-adegan memuakkan dari aktor-aktor muda briliant yang silih berganti, biarpun para penonton sudah mulai berteriak dan muntah.

Para aktor muda silih berganti menampilkan kebusukan-kebusukan terbaik mereka dari satu scene panggung ke scene panggung berikutnya, tiada malu, tiada segan, tiada sungkan lagi, sungguh ironis jika dilihat dari latar belakang intelektual mereka, mewakili golongan mana mereka berasal, sungguh sangat ironis mereka yang selama ini sangat diharapkan membawa angin perubahan di kehidupan masyarakat bangsa ini, dikagumi karena idealisme dan semangat militansi yang mereka miliki, berakhir dengan bangga mempertontonkan kehilangan nurani mereka, paradoksal yang menyedihkan.

Belum lama berselang penonton benar-benar dibuat muak, semuak-muaknya oleh panggung kebusukan dari aktor muda briliant yang memiliki keahlian di bidang perpajakan, yang sungguh apik mempertontonkan kebusukan-nya selama berminggu-minggu bahkan berbulan-bulan panggung pementasan tanpa henti.

Saat-saat sekarang ini panggung menjadi milik dan beralih kepada aktor salah satu tokoh papan atas Partai Politik Penguasa yang kebetulan juga aktor muda yang dalam sepak terjang kebusukan-nya telah sangat sukses mempertontonkan kebusukan, kemunafikan dan juga kerakusan yang luar biasa merusak, parahnya lagi dalam pertunjukan yang disajikan, aktor muda ini juga sangat sukses mempertontonkan kerjasama yang apik dengan banyak aktor-aktor muda yang lain, bak team sepak bola berkelas dalam melaksanakan kejahatannya secara berjama’ah.

Publik penonton sama sekali tidak tau kapan panggung-panggung ini akan berakhir, terlihat tanda-tanda akan berakhir-pun tidak, mereka hanya menangkap tanda-tanda bahwa kepemilikan panggung akan beralih dari satu aktor kepada aktor-aktris yang lain. Ambang batas kemuakan sudah terlewati, muntah sebagai bentuk protes fisik-pun sudah berulang terjadi, hanya satu pilihan akal sehat yang tersisa yakni “apatis”, dengan terus berdo’a dan berharap pada suatu saat kelak ada yang berhasil membubarkan panggung-panggung celaka ini…Silahkan apatis, asal jangan berhenti berteriak muak, karena di saat kau berhenti berteriak muak disaat itu pula kau membenarkan dan menerima kebenaran kebusukan yang disajikan…amit-amit.

Alih-alih panggung berakhir, mungkinkan panggung akan beralih dan menjadi milik aktor muda yang satu ini?..jika terbukti benar, yang satu ini sungguh sangat menyedihkan. Tidak kurang dari penulis sendiri menaruh harapan besar pada tokoh muda yang satu ini, yang selama ini telah berhasil mencitrakan gerakan moral yang bersih, ber-etika, cerdas, dan santun yang terpancar dari penampilan-nya yang penuh kebersahajaan. Mungkin sudah saatnya kita berhenti menaruh harapan terlalu besar kepada seseorang, terlalu naif berharap seseorang mampu membawa perubahan seorang diri di dalam sistem yang sudah terlanjur busuk luar dalam. Hasilnya adalah apa yang aku rasakan saat ini sambil menyelesaikan tulisan ini, sakit!

Masih relevan-kah saat-saat sekarang ini kita kembali menggali dan mengingat semangat Sumpah Pemuda 1908, Proklamasi 1945, Reformasi 1998, di tengah-tengah gencarnya pertunjukan panggung-panggung kebusukan kemunafikan yang tida kunjung berakhir ini??..Masih ada harapankah akan adanya perubahan di masa-masa mendatang jika tokoh-tokoh / aktor-aktor muda sudah terkontaminasi?..aktor muda yang sudah sangat mahir mempertontonkan keahliannya mengolah kebusukan?..wallahu a’lam

Masih perlukah kita meminta contoh aktor2 (muda) briliant yang dulunya getol meneriakkan idealisme, memperjuangkan kebenaran dan keadilan, tapi giliran sudah berada di dalam sistem kekuasaan justru mahir mempermainkan dan mengolah kebenaran dan keadilan menjadi semata kebenaran manipulatif demi kepentingan pragmatis mereka??..sudah terlalu banyak kawan.

Wahai Pemuda/Pemudi Indonesia dimanakah kau berada?…Ibu Pertiwi membutuhkanmu saat-saat ini, untuk menghentikan segala bentuk panggung-panggung kebusukan yang terjadi, bergeraklah…lawanlah…karena sejarah membuktikan bahwa perlawanan kalian-lah yang selama ini cukup efektif menghentikan segala kemunafikan dan kebangkrutan moral intelektual ini.

Yaa Rabb aku berlindung kepadaMu atas godaan dan ajakan nafsu berkuasa, yang sungguh membutakan…ammieen…

Awal Ramadhan 2011

Jumat, 01 Juli 2011

Profile of LNGC population worldwide

Have you guys ever imagine, what is the total population numbers of LNG Carriers from various size and type that is still operating / sailing nowadays? Well, rough guess, from several entrusted sources I had, there are total of abt. 343 units of LNGC vessels from various ages, sizes and types are still operating worldwide now. Off course out of that numbers, there are always set off between newly delivered vessels to the market with numbers of units phased out.

- Category A vessels : LNGC vessels with cargo tank capacity less then 59,999 m3- Category B vessels : LNGC vessels with cargo tank capacity in between 60,000 m3 up to 149,999 m3- Category C vessels : LNGC vessels with cargo tank capacity over then 150,000 m3 and above

There are at least 3 main groups of Cargo Tank (containment) systems, detailed as follows;

- Membrane Types systems – comprise of all basic membrane technology containment / system i.e. GTT Mk I, GTT Mk III, GT. No.82, 85, 88, GT No.96, etcThe profile is as seen on the following charts

- Spherical Types system – Mostly MOSS Rosenberg technology containment / system

- Other Types / Systems – included but not limited to ESSO, IHI SPB, Worm, Cylindrical, Bi-Lobe, etc

It’s obviously seen that LNGC vessels having (adopting) Membrane Type Technology for it’s containment system onboard are dominating the overall population numbers by 65% of the population.

III. Ages Categorizations

Normally peoples are grouping the vessel’s age under following terms and norms;

- Below 5 years old – all vessels built no more (less) than 5 years a goIV. Mixed up Categorizations

- 5 to 25 years old – all vessels built and operated sometime between last 5 years to last 25 years.

- Above 25 years old – all vessels built and operated more than 25 years back.

Some peoples are sometime also doing mixed up categorization in order to get in to a more through rough profile pictures, describing a more complex demographic distribution through out the population.

Herewith are profiles of some Mixed up categorization i.e. Age profile by OCIMF size Categorization, Age Profile by Types of Containment System, Size profile of LNGC by Containment System, etc

From which we can see at least, that most of LNG Vessels at Cat.B were built between last 5 years to the last 25 years, where else most of Cat.A vessels were built very recently (less than 5 years old).

At the same time, we could also see that most of LNGC vessels built very recently (less than 5 years old) are using Membrane types of containment system.

As to summarize the above outlined, we could conclude at least that The common size and type in the market which dominating the most population of LNGC vessels worldwide nowadays are Cat.B size of vessels with Membrane containment technology / system.

Early July 2011

Senin, 27 Juni 2011

LNG Value Chain – An Introduction to LNG, being as the alternative of a (relatively) clean energy for marine fuel

By Agung Aang on Friday, June 24th, 2011, at 03.45 PM

The Natural Gas, known as “Methane” is believed to be one of the alternative energy beside other fossil energy, that is known to be relatively clean and cheap. It’s relatively clean compare to the other sources of energy such as fuel oil, coal, etc due to methane having less carbon chain compare to others, thus in the combustion process, will produce and release less carbon emission to the atmosphere. That’s why it’s good and safer for the environment.

It’s also relatively cheap since it is believed that the global reserved is still at the sufficient level compare to the other fossil energy that had led to the scarcity all around the world. However the development of the application that uses and consumes Natural gas is still limited nowadays, especially in some third world countries (including Indonesia I guessed). In some modern countries, we saw that the people’s access in to this type of energy had been indulged since last decade.

There are at least two type of technologies (processing & containment) to deliver the Natural gas (Methane) to the customers / end-users, which first is LNG (Liquefied Natural Gas) and second is CNG (Compressed Natural Gas), this time I will start to elaborate further on LNG, we can do The CNG at some other time.

Anyway to get to know further in to this LNG thing, one has to understand first the characteristic of the LNG it self. LNG is the natural gas that has been liquefied by being cooled (thru a thermal process cooling) in to an approximately -160°C (-260°F). LNG ~ 1/600 volume of Natural Gas, making it practical to transport by ship, Can be stored and transported in insulated tanks at standard atmospheric pressure. Flammable when mixed with air concentrations between 5% - 15% (methane). Not generally considered as an explosive.

The LNG Value chain from the source fields / gas well in to the end-user are described as per-herewith diagram

As obviously seen, Natural gas which was produced from gas well, brought up through gas pipelines in to The Processing Plant where gas were liquefied and keep in liquid forms for further shipment process via an export Terminal. As earlier mentioned, gas volume in liquid faction is 1/600 times of it’s volume in original gas form, making it more practical and easier to handle during transport.

Then an LNGC will bring the gas, in liquid forms (LNG), which were kept onboard within an enclosed/insulated cryogenic containment from the Export Terminal in to the Import / Receiving Terminal, where the LNG is discharged / un-loaded in to storage and another Processing Plant, called Re-gasification Plant, where the liquefied gasses is changed back in to the gas forms before it’s virtually delivered and further distributed in to the end-users (i.e power plant, industries, etc) through gas pipeline facility.

There are at least two (2) types of The LNG Receiving Terminals being developed recently, first is On-Shore based Terminal where the Storage and Processing (Re-Gasification) Plant were located on-shore, and second is Off-Shore Terminal where the Storage and processing (Re-Gasification) Plant were located Off-Shore, it could be in a form / module of Floating Storage and Re-Gasification Plant (FSRU Barges or Vessels) and or Fixed Permanent Floating Terminal (using Gravity based, piled/fixed platforms, etc)

There are off course several pros and cons between these 2 types of Terminals, however peoples tend to explore more on the Off-Shore types recently due on the following reasons i.e. almost no land-acquisition involved (considering potential social risks), relatively faster to build, relatively less capital investment, less complex permit as well as the most issues on the mobility idea.

The most issues involved in this choice is it’s high sensitivity to the weather changes, especially rough se-condition.

Before coming to the development and application of the LNG for Marine Fuel on the next parts, to close this chapter, author would like to express his deep concern on, as of date there are none of such kind of Receiving (Import) Terminals were ever built and developed for and within Indonesia. Without any of such infrastructure made available, no wonder if the Natural Gas utility within Indonesian people in general is still low compare to other developing countries. What has become sad contradiction is, Indonesia as one of the world biggest Natural Gas Producers, sell it’s Natural gas for cheap to other countries, where it’s own Indonesian people does not have sufficient access to also enjoy the benefit of Natural Gas due to lack of (receiving) infrastructures made available.

Really sad…

End-June 2011

Kamis, 23 Juni 2011

Sinopsis Running Cost Pengoperasian Kapal - Terms for dummies II

by Agung Aang on Thursday, June 23rd, 2011 at 2:45pm

Seperti yang sudah disampaikan pada tulisan di Bag.I terdahulu (i.e.Sinopsis Running Cost Pengoperasian Kapal – Term for dummies I) istilah Running Cost dalam pengoperasian kapal, adalah bagian dari komponen biaya OPEX (Biaya total pengoperasian Kapal), diluar komponen biaya Voyage yang harus ditanggung oleh pihak Owner/Operator kapal pada waktu mengoperasikan kapal-kapal armada mereka.

Jika pada tulisan terdahulu sudah disampaikan secara detail kelompok-kelompok biaya apa saja yang masuk ke dalam kategori komponen biaya ini, maka pada tulisan kali ini penulis akan mengajak untuk melihat besaran kontribusi dari masing-masing kelompok biaya tersebut beserta proporsionalitasnya terhadap keseluruhan biaya Running Cost pengoperasian kapal.

Kita tahu bahwa Komponen Biaya Running Cost itu terdiri dari kelompok-kelompok biaya Manning (Crewing), Technical (M&R, Supplies, Stores, etc), Insurance (H&M dan P&I), General Administration & Others. Pertanyaan selanjutnya adalah seberapa besar-kah kontribusi dalam persen (%) dari masing-masing kelompok biaya tersebut terhadap keseluruhan Biaya Running Cost kapal? Bagaimana juga proporsionalitas dari masing-masing kelompok biaya tersebut terhadap keseluruhan Biaya Running Cost dari berbagai jenis dan type kapal dan operasionalnya?

Sebagai langkah awal penulis akan mengajak melihat gambaran breakdown detail kelompok biaya Running Cost dari berbagai jenis dan type kapal sebgaimana tertuang dalam tabel riset yang dipublikasikan oleh lembaga riset pasar Drewry seperti tersebut di bawah ini.

Jika dicermati lebih jauh tabel tersebut, besaran dari masing-masing kelompok biaya pada setiap jenis dan type kapal akan sangat bervariasi, namun demikian akan dapat terlihat pola yang hampir sama terjadi pada besaran kontribusi dari masing-masing kelompok biaya tersebut terhadap komponen biaya Running Cost keseluruhan pada setiap jenis dan type kapal yang berbeda.

Hal ini menarik untuk dicermati lebih jauh karena dari sejauh pengalaman penulis selama ini mengelola biaya running cost dari berbagai jenis dan type kapal, memang diyakini adanya suatu pola yang sifatnya umum (kurang-lebih berlaku untuk semua jenis dan type kapal) yakni pada besaran kontribusi dari masing-masing kelompok biaya di atas terhadap total komponen biaya running cost (secara keseluruhan) kapal.

Dari hasil telaah dan kajian penulis selama ini, pada umumnya akan terlihat pola distribusi kontribusi sebagaimana terlihat di bawah ini;

Dari sana terlihat bahwa terdapat 2 kelompok biaya utama yang selama ini mendominasi kontribusi terhadap total komponen biaya running cost kapal yakni kelompok biaya untuk Crew / Manning dan kelompok biaya Insurance (pembayaran premi H&M dan juga P&I), kedua kelompok biaya ini mendominasi kurang lebih dua pertiga dari total biaya running cost keseluruhan.

Bahkan kelompok biaya Technical (terdiri dari biaya-biaya maintenance, repair, service, supplies, stores, dll) yang selama ini dianggap paling bertanggung jawab terhadap naik-turunnya pemakaian biaya running cost kapal hanya berkontribusi kurang dari sepertiga total biaya running cost secara keseluruhan. Kebanyakan orang akan selalu berfikir bahwa untuk mengontrol ketat pemakaian anggaran biaya running cost harus dilakukan terhadap realisasi penggunaan anggaran biaya MRS (maintenance, repair dan supply). Solah-olah kelompok biaya ini senantiasa melekat dan terasosiasi kepada pelaksanaan program efisiensi dan pengetatan / pengontrolan anggaran selama ini.

Hal tersebut terjadi tentunya bukan karena tanpa sebab-sebab tertentu, salah satunya adalah karena sifat dan nature pengeluaran / realisasi expense-nya yang cenderung merata sepanjang kurun waktu anggaran, akan sangat berbeda dengan misalnya sifat pengeluaran kelompok biaya Insurance, i.e. pembayaran premi yang hanya terjadi sekali dalam satu periode anggaran. Dan tentunya juga karena kecenderungan kita melihat kelompok biaya MRS (Technical) sebagai satu-satunya kelompok biaya yang paling memungkinkan untuk dilakukannya penyesuaian kapan-pun di sepanjang paruh waktu periode anggaran, akan berbeda kasusnya jika kita bandingkan dengan biaya wages (gaji crew), yang terikat oleh kontrak perjanjian sehingga tidak dimungkinkan terjadinya perubahan pada setiap saat.

Untuk itu penulis mengajak pembaca untuk kembali berfikir dan melihat secara logis dan proporsional pada saat akan melaksanakan program pengawasan dan pengetatan (efisiensi) anggaran, bukankah sesuai pendekatan PARETO kita harus memulai dari sebagian kecil hal yang membawa pengaruh ke sebagian besar hal?

Adalah wajar jika kita diharuskan untuk melakukan pengetatan / pengontrolan secara ketat realisasi pengeluaran pada pos anggaran running cost, kita mulai dari 2 kelompok biaya utama yang berpengaruh (berkontribusi) paling besar tersebut, yakni kelompok biaya Manning dan juga kelompok biaya Insurances.

Demikian sharing kali ini, semoga bermanfaat…ammien.

End of June 2011

Selasa, 14 Juni 2011

Ship New Building, how to define fair Price? How does cost distribution of a given Price look like?

How to judge the fairness of a given New Building Price of (for example) a 6,000 DWT single Decker double hull, double bottom General Cargo vessel with IACS Class Notation for Ocean going? or New Building price for a 5,000 DWT double hull, double bottom, IMO Type I/II Oil & Chemical tanker, with IACS notation for coastal service, built locally?

To be able to do so, one has to know exactly what factors could drive the Shipyard/Shipbuilder to come up with a certain selling price for New Building construction. There are at least 2 main factors that might influence The Shipyard/Shipbuilder in defining their best quoted price for New Building in a given time.

First and foremost is The External factors, factors which are beyond their power to control, such as;

- Supply & demand situation in the market, sometime is The Builder/Seller market but some other time is a Buyer market.

- New Rules & Regulation applied, i.e. by Class, IMO, Statutory, Local Government, etc

- Steel and other commodities price level, even though some attempts could be afforded by The Shipyard to peg or hedging the price, still on some certain extends it’s beyond their competence to keep.

- Global Energy price level

- Currency exchange & borrowing rates level

- Old Tonnages phasing out rate & Scrap value rate

- Taxation scheme, etc

Secondly is The Internal factors, factors which are still within their competence to control, those are including but not limited to as follows;

- How good they manage their production cost level to stay efficient and competitive.

- How good their production system is, to maintain schedule & production phase.

- How good their project management is, one right time and one time right, right in time without fail & repetition.

- How good they manage their overhead allocation for the project.

- How good they raise and manage their project financing

- How good they manage the project risk, etc

On Shipyard / Shipbuilder’s perspective, New Building Project is normally having relatively less return compare to any Repair & Conversion Project. Thus the profit expectation for a New Building project is quite marginal compare to other project types. One of the reason is just because of the New Building project is typically having longer turn around time, hence the cost of fund is very much involved through out the project period of time.

What are the major groups of production cost, of a New Building Project, and how are they well distributed in forming a given New Building price?

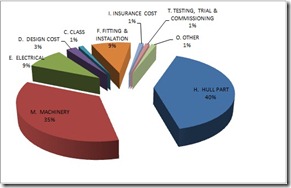

The figure below is showing the distribution pattern of each group of The Production costs of a new Building project that drive the Price.

* The figure is extracted merely from the author’s extended experiences in handling New Building Projects both at Shipyard perspective’s end as well as Owner perspective’s end. Wisely it shall be treated as guidance only, the exact and actual percentages of each might be vary on every certain specific projects.

Where the detailed of each (in the order of the biggest portion) are as follows;

- Machinery Group, in the region of 40% up to 45% – consist of all costs incurred to procure and install all the machineries and systems onboard i.e. main propulsion system, main engines, auxiliaries engines, boilers, pumps, compressors, gearbox, shafting, steering system, heat exchangers, etc

- Hull Part Group, in the region of 35% up to 40% – consist of all costs incurred to procure and fabricate all the Ship’s Hull and Deck Dept onboard i.e. Hull steel construction, rudder construction, mooring system, life saving appliances, deck piping, cargo handling systems, accommodation, coating, etc

- Electrical Group, in the region of 7% up to 10% – consist of all cost incurred to procure and install all the electrical system onboard i.e. radio communication systems, radar systems, satellite communication system, cabling, lighting, Navigation system, etc

- Fitting & Installation Group, in the region of 7% up to 10% – consist of all cost for Labor, workmanship, handling facility, etc

- Design & Class cost, in the region of 3% up to 5% – consist of all cost incurred to procure Ship’s design, Class survey & inspection service, Class Plan approvals, testing, trials & commissioning, etc

- Other miscellaneous Group, in the region of 2% up to 3% – consist of all cost incurred for the Project’s cost of fund, ceremonial, etc

The above mentioned distribution pattern, in general is likely and widely applicable to the new building of all types of vessels / ships, be it General cargo, tankers, break bulkers, bulkers, supply vessels, etc, should there be variety on the portions/percentages of each groups, let say on a particular case of the new building of a specific types of vessel i.e. FSO, FPSO, FSRU, DSV, and or other Offshore support vessels, etc, believed it won’t change the main pattern in a whole.

It’s obviously seen from such pattern, that the 2 most contributing groups are Hull and machinery, where both are contributing total 75% of the Ship’s New Building Price, these are the areas that contributing most to the New Building price. In fact the Design and Class only less contributing compare to the others, all together only less than 5% contribution to the Price.

Last but not least, by understanding the pattern well, hopefully we can have a better basis for evaluation and eventually judgment of the fairness of the Ship’s New Building Price given by any Shipyard.

June 2011

Senin, 13 Juni 2011

Shipping Business in General – Terms for dummies I

Some may ever think that shipping is such a complex world having so many terms, which some are really confusing and some time conflicting each other, the idea of serving this Note is to help one to understand better The General Shipping terms in a much easy way.

The basic economic motive of shipping is providing service to deliver/transport goods from one point of pick up (point of origin) to the point of delivery (destination point), involving two main parties i.e. The Shipper, in this case is the owner of the goods (cargo) as well as The Carrier, The one who virtually delivers the goods (cargo) to the destination, in this case is The Ship’s Owner/Operator. There are several ways of shipment i.e. Air-freight, Sea-freight and Land based-freight (trucking, train, etc). This note will serve to elaborate more on the Sea-freight, even though some basic principles might be similar and also applicable for the other 2 shipment ways.

There are two main types of Shipping, first is Liner Shipping, where sailing time is scheduled and freight rates are based on certain standard tariff, mostly for passenger, general cargoes and containers. The second one is Tramp Shipping, where sailing time is not scheduled; freight rates are negotiated and formed individually, type of cargo might be vary from general cargoes up to specific industrial cargo such as chemicals, oil & gas, coal, and other project cargoes.

In term of operating / running a Ship in the Shipping business, herewith are several basic/major shipping contract types (Charter parties), commonly used and quite popular in the market, complete with each explanations as;

- Voyage charter - It is a contract between Ship owner and charterer for transportation of a specified amount of commodity from loading port to a destination, where The Ship Owner is responsible for all the cost incurred. Normally rates are sets on a Dollar per-Ton basis of cargoes carried (Dollar per-unit cargo weight carried)

- Contract of Affreightment (CoA) - It is a contract between Ship Owner and charterer for transportation of a specified amount of commodity from loading port to a destination over a certain agreed period of time (i.e. 1 – 2 years) where The Ship Owner is responsible for all the cost incurred. Normally rates are sets on a Dollar per-Ton basis of cargoes carried (Dollar per-unit cargo weight carried)

- Trip / Tramp Charter – The contract which set and only valid for one Trip, where The Charterer is responsible for all the Voyage Costs incurred such as fuel-bunker cost, fresh water cost, ports & agency costs, etc. Freight rates are normally set on the basis of Dollar per-day throughout the no of day’s charter.

- Time Charter (T/C) - Charterer hires the vessel for a specified period of time and takes the commercial control over the vessel, where The Ship Owner is responsible for operation and capital costs, whilst Charterer is responsible for all the voyage costs. Rates are normally set on a Dollar per-day basis throughout the days of the charter period.

- Bareboat Charter - Charterer hires the vessel for a very long (specified) time, normally the whole economic life of the vessel, where Ship Owner is responsible for the capital cost only, and Charterer is responsible for all other costs. Rates are normally set on Dollar per-day basis throughout the days of the charter period. Used to be quite popular on the Energy sector market.

Along the way, some other types of lately developed contract/charter are also introduced in to the market, thus basically are the latest developed / modified version of the above mention basic types i.e.;

- Back – to – back Charter – Basically is a modified type/version of a T/C contract where the Ship owner deals with the Charterer through someone else’s, upon an agreed marginal fee’s.

- Modified Bareboat Charter – Basically is a modified type/version of a Bareboat Charter where The Ship Owner is not only responsible for the capital cost, but also some other Operational Cost (Opex) i.e. crewing cost, P&I Insurance, H&M Insurance, etc

Diagram as shown below will show the detailed flows of thought on Ship owner’s perspective with regard to the split up responsibilities and cost sharing composition amongst several types of basic contract that the ship might have upon its operation.

*Figure diagrams taken from one of slide presentation from Navigate Consulting, June 2008

Thus obviously seen the distinction amongst several areas of shipping businesses over Owning, Running and Operating a Ship or a fleet of ships, complete with each borne cost responsibilities.

That’s all what I can share on this first chapter, hopefully it could be useful and come of your help in understanding better the basic of shipping business. Insya’Allah will continue with Ship Asset Procurement & Selection on the next chapter, on some other time.

June, 2011

Jumat, 10 Juni 2011

Pelajaran Ikhlas

Ah...senyum itu serasa sdh ckp memberiku kepastian bahwa tiada sempat terpikir oleh sang pemilik senyum, jangankan pamrih dan pengharapan atas materi atau sekedar penghormatan, bahkan pahala atas kebajikan sekalipun tidak...karena senyum itu sendiri, speak for it self bahwa dia hadir sbg bentuk manifest dr satu kekuatan yg lahir dr hati ...yg kadang terasa absurd...bgmn ga absurd...panas2, berdebu, capek melaksanakan tugas dan kewajiban yg imbalannya gak seberapa dibanding resiko dan pengorbanannya, masih ditambah lagi kadang dicuekin, dianggap gila, termasuk jg disumpahin pemakai jalan yg merasa terganggu...tp msh jg mampu memberi dan menunjukkan satu bentuk rasa syukur, menerima dan menikmati, atas segala apa yang menjadi bagiannya untuk melaksanakannya dan menyerahkan sepenuhnya segala sesuatu sisanya yg bukan bagiannya kepada Allah untuk melaksanakannya.

Bagi mereka memanjatkan doa dan melaksanakan doa adalah bagian dr manusia dan selebihnya (mengabulkan doa) adalah bagian dr Allah sepenuhnya. Senyum itu cukup bercerita untuk itu, bahwa...buat pak polisi tua itu pengorbanan dalam melaksanakan tugasnya yg mulia adalah bentuk pelaksanaan dari doa2 nya yg selalu ia panjatkan kpd Allah, sedangkan dia tidak mengharapkan balasan apapun atas apa yg sdh dia lakukan atas doanya karena itu sdh menjadi bagian yg bukan lg menjadi bagiannya untuk melaksanakan.

Sungguh memang terasa absurd kekuatan/makhluk yg bernama ikhlas itu...tp sangat indah dan powerfull bagi manusia yg selalu berharap akan Ridhlo-Nya...wallahu a'lam bishawab

...Luruha galihe kangkung

...mibero koyo tapak kunthul miber

...nuliso tanpa tulisan ing papan tanpa tulisan

...kowe bakale ketemu...ning...nang...nung

...bening...tenang...dunung

Oct 2009

An Approx approach of Tonnage(GT)measurement of a Trading Vessel,as an alt instant way to calculate Ship's Tonna

Ok, again non alike to my previous note, this time I would share material that I refers to one of published book with the title of 'Naval Architecture', indeed it's a marvelous book, small book with hard cover, unfortunately I forgot exactly the author as well as the publisher of the book (since the book has recently missing somewhere) for me the book has truly like a Naval Arch pocket book for the dummies, it's very much powerful.

I referring to one of the magic formula written within the book, the formula is a lot simple and easy to remember, but in fact its quite powerful. The formula is used to calculate instantly the Gross Tonnage (GT) figure of the Trading vessels. Talking about the Gross Tonnage (GT) figure it self, for sure you'll need this figure for various purposes, one out of it is when you are about to calculate the feasibility study of buying a second hand trading vessel and later assign and or operate the vessel for a specific project. Some of the information that you might need to structure up your project costing, are a lot related to this (GT) no, those are as listed as follows;

a. In order to get some indicative of P&I premium rate figure, both for advance and supplementary call, you will need the information of the GT of the vessel going to be applied.

b. In order to get some indicative on the berthing fee (cost) of the vessel, you will also need this GT no of the vessel.

c. Some of the various Port services fee were also based on this GT no of the vessel, i.e. Assisting Tugs fee, calling / clearance fees, Mooring fee, Immigration, Port health & quarantine (if any), etc, thus are applicable for both domestic ports and or international ports.

d. The agency fee of the vessel it self on each calling Ports are also based on this GT no of the vessel.

e. Canal passing fees are also based on this (GT) no, even though each canal i.e. Suez, Panama, etc, has their each own way in defining and determining vessel's tonnage which are differs one in to others.(however the result may vary with an average minim deviation, hence as general reference IMHO we could use still this approach )

f. etc

As aforementioned, in a certain situation where you are only about to purchase a second hand trading vessel, where in this case you do not have yet a full access toward vessel's information, you would have no other choice but to calculate your own the vessel's approximately GT No's, otherwise you might not be able to complete your desk top investment study (FS) due to lack of above mentioned cost information.

Further on, in fact as far as I noticed so far, the information of vessel's GT was very seldom to be stated and mentioned within Vessel's short specs that is stipulated within Broker's Firmed Offer. Hence to be able to proceed further with your S&P plan you will have to find and calculate your own (self predict and indicate) other missing information that you need for instant GT No.

The instant magic formula is GT (T) = (L x B x D)/125

- Where L is LBP of the vessel in Ft, whilst B is Beam molded of the vessel in Ft, and D is the Depth molded of the vessel also in Ft

- In some occasion where LBP information is not mentioned, I used to use any Length (since the result would not much different, this is such an estimated figures anyway).

- Please do not mass up the units, the formula works in British Unit instead of Metric

Though it is not a long and confused formula to remember don't you? Good luck, hopes it could be helpful for all of you…ammiieen Ya Rabb Alamin.

March '09

An Empirical predictive on fuel consumption figures per-day(T)of old timer Tug Boats,i.e.Tot.Hp X 4;where does it come fro

I had notice myself that I have got the same methods of prediction at least from 5 different engineers who sailed during such type of vessels within such above mentioned period of time (70's to 80's)

I myself so used to utilize it frequently in certain situation where I've got to be answerable to my boss on the issues related to fuel consumption figure within short seconds, otherwise I might got another "Jancuk" if I failed to give an answer instantly.

After some times, I just eventually realized that the nos produced from that numerical operation, was actually not that bad, from my record analysis done very recently, I found that from various size Tug Boats (some also utility vessels), with conventional hull bodies, single screw, single engines, in between 5 to 15 years old built, from various brand of propulsion engines as long as high speed diesels, and irrespective of the applied ratings, after I ran an iteration with a norm distribution, the error margin was only within the range of 4 - 7 % (amazing huh?). Though it is enough for me for such an estimating (rough prediction)purposes only. Even though I found this very much interesting however, yet, I will not dare to test this hypothesis further in to a certain further stage of a scientific research methodology, please I'm not a scientist, it is merely on my curiosity, I do not see it falls within my areas of interest (may be some of you does?), Further on I believed that it is just a purely practitioner's approach, not more not less.

After I ran through further the numbers, I've found another fact that the error nos will increased significantly, it goes up to 10% and over, for the application toward a twin screw-twin engines Tugs, as well as for non conventional hulls (modified bow's hulls, modified flared hulls, etc), it goes between 8% - 10%. Hence ones got to be careful to apply such formula for these kind of configurations. Unfortunately I do not have an ample time to see further correlation of the nos for the application of Z-peller drive (an azimuth thruster), I'd just do not have time. All the above mentioned nos are for the application of conventional thrusters with protruded tail shafts.

Before steps further on our discussion i.e. How and where does it (the formula) come from? In order to avoid any false information, I'd like to re-highlighted that the consumption nos meant was the actual daily consumption figures after the vessels put in operation after some time and not the theoretical nor the designed nos, please take a note on this, after all these are more relevant for practitioner.

Even though the formula did not meant for theoretical consumption figures , in order to trace where does that formula come from I would use still a theoretical approaches, as you might aware, the normal daily consumption figure could be obtained from the formulas of SFOC (gr) x BHp (cont) x 24 (hr), from which we could then understand that in order to get in line with the above predictive formulas, the range of the SFOC in a certain assumption of 85% MCR (or even less) of the engine, should be at least abt.195 - 200 gr/BHp/Hr, which is true from a serial of High speed diesel engines in the output range of 750 - 2000 Hp, the SFOC was in the range of 203 - 213 gr/BHp/Hr.

In spite of various and volatile rpm applied through out the operational regime of a Tug boat, an average no of 75 - 85% MCR of engine performance during long distance voyage (more than day) continuously, is found to be quite representatives and does make senses. Thus we could use it as basis for the average actual daily fuel consumption as aforementioned.

Irrespective of all scientific proofing methodology 'IMHO' we can use the formula still, especially on a certain situation where we have to be able to get an instant idea on a predictive consumption figure of a running Tug boats or other Utility vessels, maybe on a certain situation where your boss asking you to get the answer within minutes while at the same he pointing out a gun tip over your head…then I just strongly recommend you to apply the formula…he..he..he…after all again this is just a rough predictive approaches, therefore DO NOT TRY THIS AT HOME…!

March '09

Ke-Aku-an

Ya Hallaj, kenapa pada saat aku menyebut 'Aku' diriku mendapat Murka Allah, maka terkutuklah aku, sedangkan engkau wahai Hallaj, pada saat engkau menyebut 'Aku', engkau justru mendapat Rahmat dan Cinta Nya.

Ketahuilah Wahai Iblis, menjawablah sang Pencinta Sejati, Al Hallaj, pada saat engkau menyebut 'Aku', engkau melihat kedalam dirimu, kebesaranmu, kekecilanmu, keperkasaanmu, kelemahanmu, derajatmu, dan segala2 nya tentang 'Mu', sedangkan aku tidak wahai Iblis, pada saat aku menyebut 'Aku', aku sendiri sudah tidak ada ...

Sepenggal kisah hikmah kaum Salik ...

Cukup lama saya mencoba mendalami penggalan dialogue antara Iblis dan Al Hallaj seperti tersebut di atas, sebuah dialog antara 2 kutup, kutup kepentingan (yg bersifat ego sentris) yang di wakili oleh sosok Sang Iblis dengan kutup keikhlasan yang diwakili oleh seorang manusia pencinta bernama Al Hallaj.

Bagi saya penggalan dialog di atas bukanlah semata penggalan dialog pengantar pengenalan konsep ketuhanan Manunggaling Kawulo Gusti, meskipun pada kenyataannya, tidak bisa dipungkiri bahwa sosok Al Hallaj sendiri seperti halnya juga yg kita kenal di domestik sosok Syekh Siti Jenar adalah tokoh2 yg mewakili aliran sufisme yang selalu membawa potensi polemik berkepanjangan dan tiada akhir bahkan dilingkungan kaum Ulama sendiri.

Untuk itu saya lebih suka melihat penggalan dialog di atas dalam kaca mata konsep 'keikhlasan' dan dalam dimensi 'kepasrahan' satu mahluk bernama manusia yang sedang dimabuk Cinta akan Tuhannya, Sang Pencipta, yang atas mahabbah sucinya itu dengan segala kesadaran penuh dirinya telah merelakan, meniadakan dirinya sendiri dan segala keinginan-keinginan diri, segenap obsesi, sepenuh harapan, bahkan bisikan hati yang melekat pada dirinya untuk meleburkan diri ke dalam nafas mahabbah yg menggelora atas Sang Khalik dan mereguk manisnya anggur Cinta dari sang Pencipta.

Sekarang sudah bukan saatnya lagi dalam konteks ini mempertentangkan antara sar'i dan hakikat, bahkan menurut satu hikayat Al Hallaj melaksanakan sholat sejumlah 400 rakaat dalam satu hari satu malam, setiap harinya (Subhanallah!). Bukan saatnya pula masing-masing dari kita mempertanyakan apakah ibadah yang dilakukannya berlandaskan Sunah Rasulullah apa tidak? Yang jelas ada satu ruang dimana setiap kita akan bisa melihat dalam perspektif yang sama, yaitu kepasrahan dan keikhlasan seorang manusia bernama Al Hallaj dalam menjalankan sepenuhnya peran sebagai ejawantah Kekuasaan, Kehendak, Kemauan, Pengaturan, bahkan Prerogativsm, kalau perlu pula Kesombongan Illahi di muka bumi ini, karena memang hanya Dia Sang Khaliq yang ber-hak dan mampu atas itu semua.

Bahkan klo perlu untuk itu dia harus rela dan merelakan diri dengan sepenuh ikhlas untuk dihukum penggal, picis dan di bantai di ujung pedang sahabatnya sendiri dari kalangan pencinta pula (Kaum Sufi), karena dia yakin bahwa siapapun dia yang menghukumnya (mati), yang juga telah bersaksi bahwa, bahkan potongan2 kecil bagian tubuhnya kala sudah berpisah dari tubuhnya tetap terus ber-dzikir kepada Sang Khaliq, sekali lagi siapapun dia adalah juga sebagai alat dari Sang Khaliq untuk menegakkan Ajaran (Kehendak) Sang Khaliq di muka Bumi ini. Bukankah untuk alasan itu seorang Al Hallaj baik secara kehadiran wada', bathin, eksistensi, bathin bahkan esensi, memang sudah tidak ada lagi? Yang tersisa hanyalah gelora kecintaannya kepada Kehendak Illahi.

Kalau untuk alasan itu pula di akhir kisah kematian Al Hallaj di altar Penjagalan, Sungai Tigris kemudian mengamuk, menggenangi segenap kota Baghdad tentunya bukanlah suatu tanda atas Kemurkaan Illahi, karena bagaimana mungkin Allah akan murka atas segala kehendakNya sendiri? Saya lebih melihat itu sebagai suatu bentuk luapan Mahabbah Allah atas satu KekasihNya dari bangsa manusia di muka bumi yang sudah paripurna tugas dan usahanya dalam mencari dan menggapai Cinta Hakiki, Cinta Illahi. Suatu akhir dari sepenggal dialog "Keakuan" di atas, seiring dengan tiadanya, kosongnya, hilangnya, dan dilupakannya sosok yang dulu pernah bernama Al Hallaj.

Wallahu a'lam bi shawab ...

Akhir Muharram 1430 H (2009M)

Allahumasholi ala Muhammad wa ala alihi wa shohbihi was salam ...

Sinopsis Running Cost Pengoperasian Kapal - Terms for dummies (biar kaya' P.Boed)

Sebagai gambaran awal, untuk setiap perhitungan investasi, biasa di kenal term komponen biaya OPEX (Operational expense) dan jg CAPEX (Capital expenditure i.e. biaya bunga). Dimana komponen OPEX sendiri biasanya terdiri dari dua major komponen biaya i.e. Fixed cost & Variable cost.

Komponen biaya Fixed Cost sendiri biasa dikelompokkan menjadi 2 komponen utama biaya yaitu 1.Biaya Running Cost dan 2.Biaya Depresiasi (penyusutan). Dibeberapa kasus pengamatan ada yang menyebut Biaya Depresiasi adlh salah satu bag dr komponen biaya Running Cost, namun sebagian yg lain menyebutnya tersendiri dan terpisah dari komponen biaya Running Cost, mungkin dengan alasan karena jenis dan nature yg berbeda antara Running Cost dan Depreciation cost (yang satu lebih bersifat komponen biaya real dan yg lain lbh kepada perlakuan atau accounting treatment), namun yang jelas terlepas dari istilah dan pengelompokannya yg berbeda, yang jelas keduanya merupakan bagian dari komponen biaya Fixed Cost.

Dikatakan sbg bag komponen biaya Fixed cost, karena Running cost (i.e. biaya berjalan) adalah jenis komponen biaya yang melekat setiap saat pada setiap pengoperasian kapal, baik kapal itu sedang beroperasi dalam modu komersial maupun non komersial (misalkan pada saat kapal sedang dalam perawatan i.e. docking,etc), tetap komponen biaya Running cost ini akan muncul dan applicable (dikenakan) pada biaya kapal ybs. Istilah "becakan-nya", biar kata kapal mau diem, nongkrong tiap hari atau mo belayar trus2an tanpa henti tiap harinya, tetap komponen biaya ini akan jalan terus (kaya' argometer taxi)

Komponen biaya Running Cost ini biasa diwujudkan dalam bentuk satuan jumlah biaya dlm Rp atau US$ / hari dari pengoperasian Kapal tertentu, misalkan kpl MV.AA, adlh jenis kapal Anchor handling yang sedang di charter oleh satu Oil Coy tertentu memiliki RC diluar deprec sebesar US$ 2,500.-/ hari, maka yang terjadi adlh apakah kapal tsb mau setiap hari dioperasikan oleh pihak pencharter u/ anchor jobs ataukah hanya diam sekedar dioperasikan u/ standby uses, maka tetap u/ setiap harinya akan muncul biaya sebesar minimal US$ 2,500.- untuk kpl yg bersangkutan.

Adapun komponen biaya-biaya apa sajakah yang masuk ke dalam kelompok biaya Running Cost ini?Komponen biaya Running Cost (RC) dapat dikelompokkan menjadi kelompok biaya2 utama sbb;

1. Kelompok Biaya Asuransi (Insurrance), yg terdiri dr komponen2 biaya sbb;

- H&M (Hull & Machinery) - yaitu komponen biaya asuransi kapal, yg besarannya tergantung dr jumlah nilai pertanggungan dr kapal dan juga besaran presentase H&M rate yg di quote oleh pihak Underwriter.

- P&I (Protection & Idemnity) - yang terdiri dari komponen biaya advance call dan supplementary call (mirip "arisan"), yg besarannya tergantung dari GRT kapal dan jg besaran presentase rate yg di quote oleh masing2 Marine Club.

2. Kelompok Biaya Technical, yg terdiri dr komponen2 biaya sbb;

- Komponen biaya Maintenance (perawatan) - besarannya adlh merupakan fungsi dr faktor2 i.e. jenis kpl, umur/usia kpl, besaran DWT / GRT kpl, Tot HP kpl, dll, sbg turunan dr pelaksanaan PMS dimasing2 kpl.

- Komponen biaya Repair (perbaikan) - pendekatan thd besarnya kurang lebih sama dengan komponen biaya perawatan, tp yg jelas kecenderungannya post biaya ini akan selalu lbh kecil dr post biaya sblmnya.

'- Komponen biaya Pembaharuan - pendekatan thd besarnya kurang lebih sama

'- Komponen biaya Certification & Survey - pendekatan thd besarnya kurang lbh sama, plus dengan memasukkan tambahan factor trading area dr masing2 kpl.

'- Komponen biaya Docking - pendekatan thd besarnya kurang lebih sama, plus dengan memasukkan tambahan faktor jenis regular docking yg akan dilaksanakan, namun yg jelas treatment akuntansi-nya akan agak sdkt berbeda dng post2 biaya yg lain.

3. Kelompok Biaya Supply, yg terdiri dr komponen2 biaya sbb;

- Komponen biaya Supply for Spares & parts - besarannya adlh merupakan fungsi dr faktor2 i.e. jenis kpl, umur/usia kpl, besaran DWT / GRT kpl, Tot HP kpl, dll, sbg turunan dr pelaksanaan PMS dimasing2 kpl.

- Komponen biaya Supply for Stores & sea-stocks - pendekatan thd besarnya kurang lebih sama

- Komponen biaya Supply for Docking - pendekatan thd besarnya kurang lebih sama, plus dengan memasukkan tambahan faktor jenis regular docking yg akan dilaksanakan, namun yg jelas treatment akuntansi-nya akan agak sdkt berbeda dng post2 biaya yg lain.

4. Kelompok Biaya Marine Personnel Dept (MPD), yg terdiri dr komponen2 biaya sbb;

- Komponen Biaya Crew (Wages) - besarannya adlh merupakan fungsi dr faktor2 i.e. jumlah crew dan komposisi crews (STCW), jenis kpl, DWT/GRT, Tot HP kpl, dll.

- Komponen biaya Union - miss ITTU, etc

- Komponen biaya Komunikasi kapal - pendekatan thd besarnya kurang lebih sama

- Komponen biaya Repatriasi (sign on & off)

- Komponen biaya Victualling (Belanja makan) - pendekatan thd besarnya kurang lebih sama

Sebagai catatan, untuk kelompok biaya 2. Technical dan 3. Supplys, dibeberapa Industrial standard & practices (i.e. Clarkson, Drewry, BQ, etc) biasa jg disebut kelompok biaya MRS (Maintenance, Repair & Supplies). Adapun besaran dan trends dr masing2 kelompok dan komponen biaya seperti tsb di atas bisa di lihat dan di access dari berbagai hasil review industrial yg biasa dikeluarkan (di release) scr berkala oleh misalnya lembaga research seperti Clarkson, Drewry, BQ, etc, applicable u/ masing2 jenis kapal, range ukuran tertentu dan jg range usia / umur kpl tertentu pula.

Untuk menutup catatan ini, perlu jg kirannya disampaikan bahwa dari sifat dan jenis pencatatan keuangannya, Running Cost (RC) sendiri dapat dibedakan dan dikelompokkan menjadi 2 jenis / kelompok yaitu 1. Recurring cost dan 2. Current Cost.

Dimana yang dimaksud dengan Recurring cost adlh jenis2 komponen biaya dr Running Cost (RC) yang berdasarkan sifat pencatatannya (berdasarkan practice & principle of accounting yg berlaku) bisa diperlakukan sbg biaya yg ditangguhkan dalam artian tidak harus dicatat sbg expense dlm satu periode tahun fiskal, yang termasuk dalam kelompok biaya ini adlh miss jenis biaya Differred Charged Docking, Docking Amortization and or Provision, etc, dimana beban biaya yg dimaksud bisa di spread out dlm kurun waktu tertentu dan tidak sekaligus di expense dlm satu waktu i.e. misalkan di spread out dlm kurun waktu 30 bln sesuai dengan periodisasi regular docking period.

Sedangkan kelompok yang lain adalah kelompok biaya Running Cost yg harus dicatat sbg expense dan habis dalam kurun waktu satu tahun fiskal yg sama, contohnya adlh semua biaya RC yg bukan diperuntukkan untuk Docking dan Pembaharuan.

Demikian dulu Boss catatan dr ane sementara ini, selanjutnya untuk Mixed up Composition and each Contribution in percentage proportional dr masing2 Post Running Cost seperti tsb di atas dan juga Mixed flows dan mainstream dr RC suatu kapal terhadap fungsi waktu (F(t)), akan saya coba tuangkan dan sampaikan tersendiri di catatan berikutnya, klo gak males...he..he..he...(read"lek gak aras-arasen")

Semoga Bermanfaat

Medio June 09

Bumi Nusantara merindukan sentuhan kepemimpinan seperti era kepemimpinan sosok Sang Mahamantrimukya Mpu Mada

Aku benar2 sulit membayangkan kejayaan semacam apa yang telah beliau capai pada saat itu, dengan melihat semua fakta catatan sejarah masa lampau yang tergambar di atas. Dan yang lebih membuatku kagum bin terkesima adalah fakta bahwa beliau bisa mencapai segala pencapaian sebagai perwujudan impiannya seperti itu dalam rentang waktu yang kurang dari 30 thn saja (klo gak salah di pertengahan abad 13)

Dari sosok seorang Gajah Mada sendiri aku mendapatkan kesimpulan setidaknya untuk diriku sendiri, bahwa beliau adalah gambaran sosok seorang yang sederhana dari kalangan rakyat jelata (bukan dari kalangan bangsawan / Arya), yang mengawali segala sesuatunya dari bukan siapa-siapa. Namun yang semata sederhana dan bukan siapa-siapa itu telah membuktikan bisa dan mampu untuk bermimpi besar, berusaha dan bekerja sangat keras, termasuk menyisihkan segala kesenangan pribadi dan segenap interest diri lainnya demi untuk mewujudkan segala impian besarnya.

Tidak banyak catatan sejarah yang berhasil mengungkap siapa jati dirinya yang sesungguhnya, dari mana berasal, dari keluarga siapa, siapa orang tuanya, bahkan kapan dan dimana beliau wafat (apa bener?), termasuk makam dan petilasannya tidak diketahui orang. Sebagian orang hanya mengetahui bahwa beliau mengawali kareer dibidang keprajuritan (kemiliteran) dan berakhir sebagai Mahapatih Amangkubhumi dizaman keemasan Majapahit, diera duet kepemimpinan Prabu Hayam Wuruk dan Mahamantrimukya Mpu Mada, itu saja. Yang selalu akan diingat orang selain dari segala pencapaian kejayaan buah dari segenap kerja kerasnya adalah sumpah beliau yang terkenal i.e. "Sumpah Palapa", yang diucapkan diawal beliau menerima mandat dan kepercayaan dari Sang Prabu sebagai Mahapatih Amangkubhumi, sebagian orang mengartikannya sebagai sumpah untuk tidak memakan buah Palapa, sebelum tercapai segala cita-citanya untuk tanah air Majapahit, sebagian lagi mengartikannya sebagai cetusan sumpah yang menggambarkan pilihan garis hidupnya untuk lebih memilih "Hamukti Lara Lapa" yang kurang lebih berarti lebih memilih hidup dalam puasa (tirakat) atas segala kesenangan dan nikmat duniawi disepanjang hidupnya untuk suatu tujuan yang telah dicita-citakan, dan daripada sekedar "Hamukti Wiwaha" seperti halnya kebanyakan cita-cita manusia hidup di dunia pada umumnya, yaitu kemulyaan hidup dengan segala kebahagiaan dunia, keluarga, kemakmuran, kejayaan pangkat, kemuliaan dimata masyarakat, dsb.

Pilihan hidup yang beliau ambil itulah yang menjadi salah satu sumber inspirasi dalam catatan-ku saat ini, disamping ambisi besar yang beliau abdikan demi kejayaan bangsa dan negaranya.Tidak banyak orang yang berani dan mampu bermimpi besar untuk sesuatu, demikian pula tidak banyak orang yang pada akhirnya berhasil mencapai dan mewujudkan impian dan cita2nya. Terlebih2 lagi jika hal itu terjadi di masyarakat dengan akar budaya 'Jawa' yang terkenal "nriman ing pandhum". Orang yang memiliki ambisi dan cita2 yang terlampau besar menurut ukuran masyarakat-nya, akan cenderung mendapat cibiran dan cemoohan mulai dari jangan terlalu muluk2, awas keblinger, dll. Tidak kurang hal yang sama juga terjadi dan dialami sendiri oleh Sang Mahapatih Gajah Mada pada saat pertama mengumandangkan sumpahnya di hari penobatan dirinya di Tratag Rambat Bale Manguntur (istana) Wilwatikta, tidak kurang dari rekan2 dekat-nya sendiri bahkan pula Sang Raja Putri Paduka Kembar menertawakan isi sumpah Sang Mpu Mada, dan menganggap isi sumpah itu tidak lebih dari sebatas guyonan hiperbolis Sang Mahamentrimukya.

Namun tidak demikian dalam pandangan Gajah Mada, yang menurut kesan yang saya dapat adalah sosok manusia yang kuat, baik dalam arti yang sesungguhnya secara fisik lahir yang dimiliki dan juga kepribadian yang kuat. Dalam pandangan Gajah Mada, hal2 apa yang menurut pandangan orang pada umumnya tidak dapat dicapai atau terlalu tinggi untuk dicapai bukan berarti tidak dapat dicapai, apalagi untuk seorang Gajah Mada yang mengucapkan segala sumpahnya dengan segenap hati yang tidak sekedar dengan mulut. Gajah Mada yang saya kenal bukanlah pula sosok yang bodoh yang hanya ngomong sekedar njeplak, yang tidak faham betul atas konsekuensi apa yang harus ditanggung dengan terucapnya Sumpah itu, bahkan menurut saya dia adalah sosok yang cerdas, justru karena dia tahu bahwa apa yang diucapkannya bukanlah hal yang mustahil, maka beliau merelakan segala kepentingan yang melekat pada dirinya. Masih menurut pandangan Gajah Mada, tidak ada yang mustahil dengan cita2nya, klo dibutuhkan usaha yang ekstra keras untuk mencapai cita2 itu, ya itu pasti, oleh karena itu sebagai gantinya beliau merelakan segala kebahagiaan dan kesenangan hidupnya, bahkan termasuk tidak menutup kemungkinan juga terhadap keinginan untuk berkeluarga, beristri, dan memiliki keturunan, jika hal itu dipandang akan berpotensi menjadi penghalang dirinya terhadap pencapaian cita2nya, tidak akan ragu dia meniadakan keinginan seperti itu.

Kalau toh catatan sejarah dikemudian hari menunjukkan bukti2 dan fakta keberhasilan usahanya untuk mencapai cita2-nya yang besar tidak lebih dan tidak kurang adalah karena segala usaha kerasnya dan juga laku tirakatnya dengan mengesampingkan segala kesenangan dan kebahagiaan hidupnya sebagai bagian dari usaha mendekatkan diri dengan Tuhannya untuk mencapai cita2nya yang berlangsung selama bertahun-tahun (bahkan puluhan tahun). Banyak hal yang harus dibayar mahal atas segala usaha dalam mencapai cita2nya, tanpa secuilpun keraguan, dengan pendekatan tanpa kompromi dan dengan konsistensi langkahnya, tidak kurang dari hambatan dan kendala dari Sang Raja-nya sendiri Sang Gagak Ketawang, dalam tragedi Perang Bubat yang tragis, segala sesuatu akan dia libas jika dia lihat sesuatu itu akan berpotensi. menghalanginya dalam mencapai cita2nya.

Terlepas dari segala pendekatan2nya yang cenderung bertangan besi, yang tidak kenal kompromi, tidak kenal ragu-ragu, satu hal yang tetap membuat saya takjub, adalah kebesaran hatinya dan mungkin juga sebagian adalah juga ketetapan hatinya, yang ditunjukkan dalam menyikapi murka Sang Raja setelah perang Bubat usai, dengan menerima secara ikhlas dan rela segala keputusan Sang Raja yang manandai akhir karir kepemimpinannya, tanpa sedikit-pun tergoda untuk mengambil alih kekuasaan Sang Raja yang Murka padanya, meskipun jika melihat konteks situasi dan suasana saat itu hal itu sangatlah mungkin beliau ambil, mengingat akar pengaruhnya pada saat itu di perangkat negara Majapahit dimungkinkan melebihi akar pengaruh dari Sang Raja sendiri. Namun demikian disitulah tampak dengan jelas letak kenegarawanan Sang Gajah Mada, dengan telah mengambil sikap untuk lebih mementingan sumpah sucinya yang dilamari semangat mengabdi dan berbakti kepada Bumi Pertiwi Majapahit dan bukanlah semata atas dan untuk kejayaan dirinya sendiri.

Itulah, tentunya tidaklah terlalu mengherankan jika diakhir hayatnya, beliau cenderung mengasingkan diri, beliau berpesan tidak menginginkan dirinya di candikan atau dibuatkan petilasan atau sebatas makam (bahkan sebagian orang lebih sering menyebutnya Moksa daripada mati), karena beliau sama sekali tidak menginginkan orang2 dikemudian hari lebih mengenang dirinya daripada Majapahit sendiri. Sebuah paket pilihan hidup yang sudah beliau ambil berpuluh tahun sebelumnya.

Dalam konteks ajang pemilihan kepemimpinan Nasional dewasa ini, kembali terbersit pertanyaan menggoda di kepala saya…siapa yach dari kontestan yang ada yang sanggup dan bisa mewarisi semangat Sang Gajah Mada dalam mengharumkan bumi Nusantara ini? atau setidaknya siapa yach yang memiliki karakter yang mirip?, atau mungkin kiranya siapa yach yang berani dan rela mengambil pilihan hidup seperti dia? untuk kemudian ditutup dengan pertanyaan .."kira2 kapan yach bangsa Nusantara ini kembali mendapatkan sentuhan kepemimpinan seperti Sang Mahamentrimukya?Bukankah sejarah berulang?Bukankah sejarah adalah juga media untuk mewariskan semangat?...Wallahu a'lam bis shawab.

Tribute to P. Langit Kresna Hariadi dengan mahakaryanya "Gajah Mada"

March '09

Safety requirements Vs Cost Efficiency, Pandora's Box for Fleet Manager?

Yet, understanding people consciouseness to the issues of safety, most people are used to see,and understanding the underlying msg behind such jargons merely as a reminder to be carefull (in fact safety does not have direct correlation with any carefull and or careless), some of them are even worst, by digesting the msg merely as an organization or coy's "pride", as blindly campaign for sake of fulfilling a certain standard, or even maybe as much as their effort to win a certain bid-qualification where safety concern is one of eliminating factors. Most of them are used to forget that safety is a mind-set, safety is a behaviour, and safety is an action, anyway I dont want to elaborate further this phenomenon this time, maybe some other time.

This time I'd just like to invite all of your critical views in understanding and eventually responding to a certain quotes of "How to compromize safety requirement with cost efficiency?" first and foremost and "Is there a really compromizing sone between both aforementioned?". I saw this as become a never-end dialogues ever, especially for those who had been in control to manage both issues together, though this is quaite relevant to my friend who are now managing or dealing with fleet, be it as ship manager and or as owner operator. Hopes some of you may find this discussion as interesting as I did.

It has become no more secret if one says, safety will always come with a high cost. One logic consequence of a high standard safety requirement is cost burden. Sometime even in a certain case, safety will bring up a degree of redundancy toward overall system (configuration) that again will end-up with a high cost. Whilst in other hand as a Fleet Manager we have to be able in control of cost as a key success factor to stay competitive and stay exist in the thought industry competition. This is become very much relevant recently, where a ressession cloud are haunted in almost all industry not exclusively marine & shipping industry. Of which, it seems we do not have any other choices but implementing a radical approaches of cost efficiencies at all sectors to be able to stay operationally and costly excellent.

Firstly I would say that, may be I'm the one of those who does not believe there is a compromizing zone between safety requirement and cost efficiency, I'm the one who strongly believes that one (amongst others two) could not exist by neglecting others, for one kind of me, we do believes that there isn't such zone and area where we could compromizing safety for sake of cost efficiency. I myself will always believes safety abundant will always end-up with a tremendeously and very much costly disaster ever. Even though at the same time I do also have the same agreement with those who think that cost efficiency is an inevitable.

For me safety concern and cost consciousness are two different animals that are not impossible to get along, it will never crossing each others. Couple weeks back, one colleague of mine threw me a simple question "How much of a high standard hard hat (safety helmet) aproved by all safety standard will cost us each?" do you ever know what is the exact answer is? according to my colleague, he got a source that could sell those at Rp.25K Rups/each, before discount. Some time some of us might think those kind of PPE must be very much expensives, in fact it is not, for sure things may get definetely different if we come to a high standard safety supplier/provider (alike convenience stores), do not get shock if we will find a huge different in cost for the same things. This is just a small, simple exsample as to give you an idea that safety standard could be afforded for cheap by a certain different approach.

Afterall I sees, safety requirement and standard it self is not a kind of things worth to be compromized, but the way to achieve them are absolutely worth to be compromized. Our manner, our comfort, our convenience in fulfilling those standard and requirement is the one that is really worth to be compromized without sacrificing our cost efficiency approaches. Out of which I could see that both safety and cost efficiency could get along still, through a certain ways to manage them well without intercepting one into others at all time.

Nevertheless management approaches such as consistently in planning, executing, control and evaluating is key success factors to well translate the strategic issues between safety and cost consciouseness in to actions. Again if one still stubborn poking my nose with question of "Which one come to your priority?" I would be confident enough to give an answer that safety is my priority, as a prudent manager we have to buy an insurrance policy don't we?...yes, all given cost for safety standard would become our premium that we got to pay in order to get the assurrances of safe working practices at our working environment, at least that is as of me.

March, 2009